When choosing between plywood and MDF for cabinet woodworking, consider their strengths and finishes. Plywood offers better durability, moisture resistance, and a natural grain look, making it ideal for heavy-use and furniture that lasts. MDF provides a smooth surface perfect for painting and detailed designs, and is easier to work with. Both have different costs and environmental impacts. If you’re unsure which suits your project, exploring these details further will help you make an informed choice.

Key Takeaways

- Plywood offers better strength, moisture resistance, and durability, making it ideal for heavy-use and humid environments in cabinets.

- MDF provides a smooth, uniform surface perfect for painted finishes and intricate detailing, but is less moisture and impact resistant.

- Plywood tends to be more expensive but has natural grain patterns and can be finished with veneers for aesthetic appeal.

- MDF is more affordable, easier to work with, and suitable for detailed painting or surface treatments in cabinetry projects.

- For eco-friendliness and recyclability, plywood generally has an advantage over MDF, which contains adhesives and resins that complicate recycling.

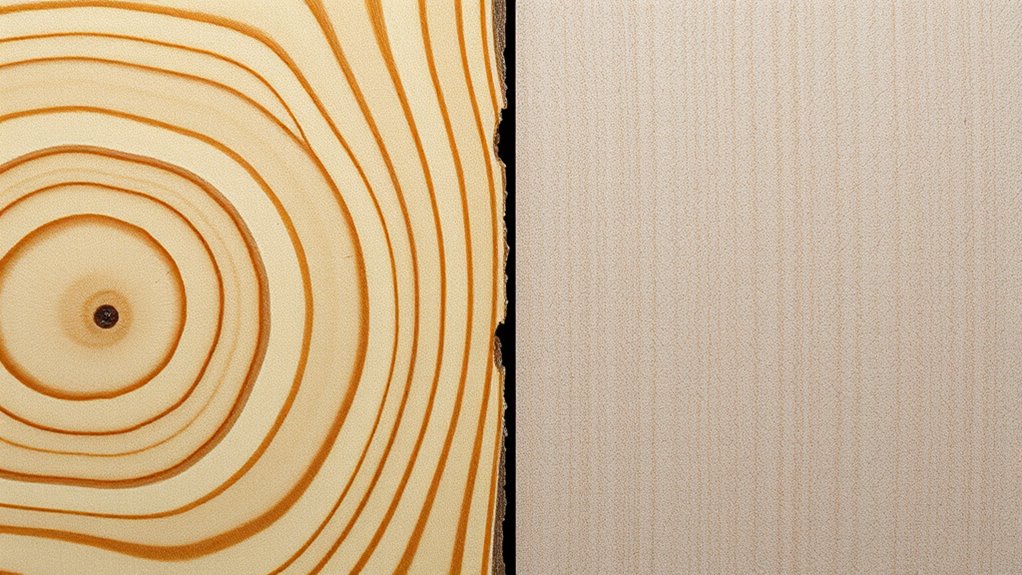

Understanding the Composition of Plywood and MDF

Understanding the composition of plywood and MDF is essential for making informed decisions in cabinet woodworking. Plywood is made of multiple thin veneer layers glued together with the grain patterns running in alternating directions. This construction gives it a natural, recognizable grain pattern and a smooth surface texture, which enhances its aesthetic appeal. In contrast, MDF consists of fine wood fibers bonded with resin under high pressure, resulting in a dense, uniform material. Its surface texture is smooth and consistent, making it ideal for painted finishes. While plywood displays distinctive grain patterns that add character, MDF lacks visible grain, providing a sleek, even surface. Knowing these differences helps you choose the right material based on the desired appearance and surface qualities for your cabinets. Additionally, understanding the manufacturing processes behind each material can help assess their durability and suitability for specific projects.

Comparing Strength and Durability in Cabinet Applications

When choosing materials for cabinet construction, evaluating their strength and durability is essential to guarantee long-lasting results. Plywood offers excellent strength due to its layered grain patterns that resist warping and splitting over time. Its durability makes it suitable for heavy-use areas. MDF, on the other hand, has a denser structure with uniform grain patterns and fewer weaknesses, but it can be less resistant to moisture and impact. Color variations in MDF are minimal, providing a consistent look, while plywood’s grain patterns can vary, influencing its appearance. If you need sturdy, long-lasting cabinets, plywood’s strength and resilience often give it an edge. However, for smoother surfaces with less concern about moisture, MDF can still provide durable performance in less demanding applications. Incorporating quality assurance practices in material selection can help ensure your cabinets meet longevity expectations.

Visual Appeal and Surface Finish Options

Choosing the right material for your cabinets also depends on their visual appeal and surface finish options. Plywood offers a natural look with decorative veneers, allowing you to customize grain patterns and colors for a refined appearance. MDF, on the other hand, provides a smooth, uniform surface ideal for painted finishes or intricate surface textures. Vetted – Grobal World Both materials can accommodate various surface textures, from matte to high-gloss, depending on your design preferences.

Cost Differences Between Plywood and MDF

While both plywood and MDF offer versatile surface options for cabinets, their cost differences can substantially impact your budget. Generally, MDF is more affordable, making it a budget option for projects with tight material costs. Plywood tends to be pricier but provides strength and durability. Here’s a quick comparison:

| Material | Average Cost per Sheet | Best For |

|---|---|---|

| Plywood | $50 – $120 | Heavy-use cabinets |

| MDF | $40 – $70 | Smooth finishes |

| Price Range | $10 difference | Budget considerations |

| Durability | Higher for plywood | Long-term projects |

| Surface | Less prone to warping | Flat, painted surfaces |

Ultimately, your choice depends on balancing material costs with your project needs. For projects requiring a high-quality finish, professional-grade materials like MDF may offer advantages despite the cost.

Ease of Cutting, Shaping, and Assembly

Compared to plywood, MDF is generally easier to cut, shape, and assemble due to its uniform, dense surface and softer composition. Its consistent material allows for cleaner cuts and precise shaping without splintering. This makes joint strength more reliable, especially when using screws or glue, since the surface provides better adhesion. Additionally, surface preparation is simpler—sanding MDF smooths out edges and surfaces quickly, improving finish quality. You’ll find that working with MDF requires less effort to achieve clean results. Keep in mind, though, that MDF can produce fine dust, so proper dust collection is essential. Overall, MDF streamlines the process of cutting, shaping, and assembling, making it a popular choice for detailed cabinetry work.

Resistance to Moisture and Environmental Factors

When choosing wood for cabinets, you need materials that resist moisture and environmental changes. Understanding moisture resistance capabilities helps you pick woods that won’t warp or swell over time. Considering environmental stability factors guarantees your cabinets stay durable and looking great in any setting. Incorporating material properties can further ensure long-term performance and resilience against varying conditions.

Moisture Resistance Capabilities

Moisture resistance is a key factor to contemplate when choosing cabinet wood, especially if your project will be exposed to humid environments or fluctuating temperatures. Plywood generally offers better water damage resistance due to its layered construction, making it more suitable for moisture prevention. MDF, on the other hand, is less resistant to water and can swell or warp if exposed to high humidity. To improve moisture resistance, consider sealing or applying waterproof finishes to MDF surfaces. Plywood’s natural structure helps it withstand moisture better, reducing the risk of warping or damage over time. Keep in mind, proper sealing and maintenance are essential for both materials in environments prone to moisture. Additionally, sound vibrations are believed to enhance cellular regeneration and overall health, which can be beneficial in maintaining the integrity of wood materials over time.

Environmental Stability Factors

Have you considered how environmental factors beyond moisture, like temperature fluctuations, UV exposure, and air quality, can impact your cabinet’s durability? These elements influence the long-term stability of your materials. Plywood generally handles temperature swings better than MDF, which can swell or warp with humidity changes. Additionally, high UV exposure can cause discoloration, especially in MDF, which may degrade over time. Indoor air quality is vital; low VOC emissions are better for your health and help maintain a stable environment. MDF often emits more VOCs, impacting indoor air quality negatively. Choosing materials with low VOC emissions ensures your cabinets remain environmentally stable and safe, reducing potential warping, cracking, or health concerns over time.

Environmental Impact and Sustainability Considerations

When choosing materials for your cabinets, consider eco-friendly options that diminish environmental impact. It’s also important to check formaldehyde emissions to ensure healthier indoor air quality. Additionally, think about recyclability and waste management to make your project more sustainable.

Eco-Friendly Material Choices

Choosing eco-friendly materials for your cabinet woodworking projects not only benefits the environment but also guarantees sustainability over the long term. When selecting materials, consider recyclability considerations to assure that your cabinets can be responsibly disposed of or repurposed. Look for eco label certifications, which verify that the materials meet strict environmental standards, reducing your ecological footprint. These certifications help you identify sustainably sourced options and promote responsible manufacturing practices. Using eco-friendly materials can also improve indoor air quality and support conservation efforts. Keep these tips in mind:

- Prioritize materials with clear recyclability considerations

- Choose products with recognized eco label certifications

- Opt for sustainably harvested or recycled raw materials

- Incorporate environmentally conscious sound design principles to reduce overall environmental impact.

Making mindful choices today ensures a greener future for your woodworking projects.

Formaldehyde Emissions Levels

Since formaldehyde emissions can substantially impact indoor air quality, evaluating the levels produced by your chosen materials is essential for sustainable woodworking. Plywood typically emits lower VOC emissions compared to MDF, which often contains formaldehyde-based resins. High formaldehyde levels can compromise indoor air quality, posing health risks over time. To compare, consider this table:

| Material | Formaldehyde Emissions | VOC Emissions |

|---|---|---|

| Plywood | Low | Moderate |

| MDF | High | High |

Choosing low-emission options helps safeguard your indoor air quality and reduces environmental impact. Always look for certifications like CARB or FSC to ensure your materials meet strict formaldehyde standards. Prioritize sustainable choices for healthier indoor environments, especially considering AI safety measures to evaluate material emissions effectively.

Recyclability and Waste

Have you considered the environmental impact of your woodworking materials through their recyclability and waste? Plywood generally has a higher recyclability potential because it can often be reclaimed or repurposed, reducing waste. MDF, on the other hand, contains binders and adhesives that may complicate recycling efforts and lead to more waste when discarded. To minimize your environmental footprint, focus on waste reduction by choosing materials that can be reused or recycled easily. Recycling methods for MDF can be more limited compared to plywood, making proper disposal even more important.

- Plywood’s layered structure makes it easier to recycle or repurpose.

- MDF’s composite nature can limit recyclability potential and increase waste.

- Proper disposal methods and recycling programs help lower your project’s environmental impact.

Choosing the Right Material for Your Project Needs

Selecting the right material is essential for ensuring your woodworking project turns out just as you envision. Consider how grain patterns and surface textures impact the final look and feel. Plywood offers consistent grain patterns and smooth surfaces, making it ideal for clean, modern designs. MDF provides a uniform surface texture, perfect for painting or detailed finishes. To help you decide, here’s a quick comparison:

| Material | Grain Patterns | Surface Textures | Best Use |

|---|---|---|---|

| Plywood | Visible, varied | Smooth, consistent | Shelves, doors |

| MDF | Minimal, uniform | Very smooth | Painted cabinets |

| Particleboard | None | Slight roughness | Budget projects |

Your choice depends on your aesthetic preferences and project requirements. Additionally, understanding woodworking materials can help you make more informed decisions for your specific project needs.

Frequently Asked Questions

How Does Each Material Affect the Overall Weight of the Cabinet?

When considering weight, think about how each material impacts your cabinet’s overall mass. Plywood tends to be lighter than MDF, making it easier to handle and install. This influences weight considerations and affects structural integrity, especially for larger cabinets. MDF is heavier, which might provide added stability but requires stronger supports. Your choice should balance weight considerations with the structural needs of your project, ensuring safety and durability.

What Are the Long-Term Maintenance Requirements for Plywood and MDF?

Imagine your cabinets whisper secrets about their lifespan—long-term maintenance reveals their true durability. Plywood demands less frequent upkeep, thanks to its superior durability and resistance to moisture, but it’s more environmentally impactful due to its material sourcing. MDF, while easier to work with, needs careful sealing and handling to prevent damage over time. Consider both durability concerns and environmental impact when planning your cabinet’s future, ensuring it stays beautiful longer.

Can Both Materials Be Used for Custom Finishes or Painting?

You can definitely use both plywood and MDF for custom finishes or painting. Both materials accept decorative finishes well when you properly prime them using specific priming techniques. MDF provides a smooth surface ideal for painting, while plywood offers a natural look that can be stained or painted. Just make sure you prepare each surface correctly to achieve the best results with your custom finishes.

Which Material Is More Suitable for High-Humidity Kitchen Environments?

In humid habitats, you want materials that stand strong against moisture. Plywood’s proven permeability offers better moisture resistance, making it more suitable for high-humidity kitchens. Its durability withstands damp conditions better than MDF, which can swell and weaken when exposed to moisture. So, for a resilient, reliable, and moisture-resistant kitchen, plywood provides superior strength and stability, ensuring your cabinets stay in shape despite the steamy environment.

How Does the Availability of Each Material Vary Regionally?

You’ll find that regional sourcing impacts the availability of plywood and MDF, causing material scarcity in some areas. In regions with abundant timber resources, plywood is more accessible and affordable, while MDF might be less common. Conversely, urban centers or places with limited wood supply often experience shortages of both materials. Your choice depends on local market conditions, so check regional sourcing options to guarantee you get the best material for your project.

Conclusion

So, whether you pick plywood’s rugged charm or MDF’s smooth talk, just remember: your cabinets will tell a story. Will they be the sturdy heroes or the sleek sophisticates? Either way, you’re the boss. Just weigh your needs, budget, and style—and don’t forget to enjoy the chaos of choosing, cutting, and assembling. After all, what’s life without a little woodwork drama? Happy building!