Electromechanical scoring systems use sensors to detect performance parameters like position, vibration, and temperature. These sensors send signals to control units that process and convert the data into meaningful information through filtering and digitization. Mechanical actuators then respond to this data to perform tasks or adjustments. Regular calibration guarantees accuracy and reliability. By combining electronic and mechanical components, these systems deliver fast, consistent results and reduce human errors—exploring more reveals how they keep performance assessments precise and efficient.

Key Takeaways

- Electromechanical scoring systems use sensors and actuators controlled by electronic units to detect and record performance data.

- Sensors capture parameters like position, vibration, or temperature, which are processed through filtering and digitization.

- Signal processing algorithms, including neural networks, analyze sensor data to identify scoring outcomes or faults.

- Electronic Control Units (ECUs) coordinate data collection, perform calculations, and transmit results for assessment.

- Regular calibration and secure communication ensure accuracy, reliability, and protection against tampering or cyber threats.

Components of Electromechanical Scoring Systems

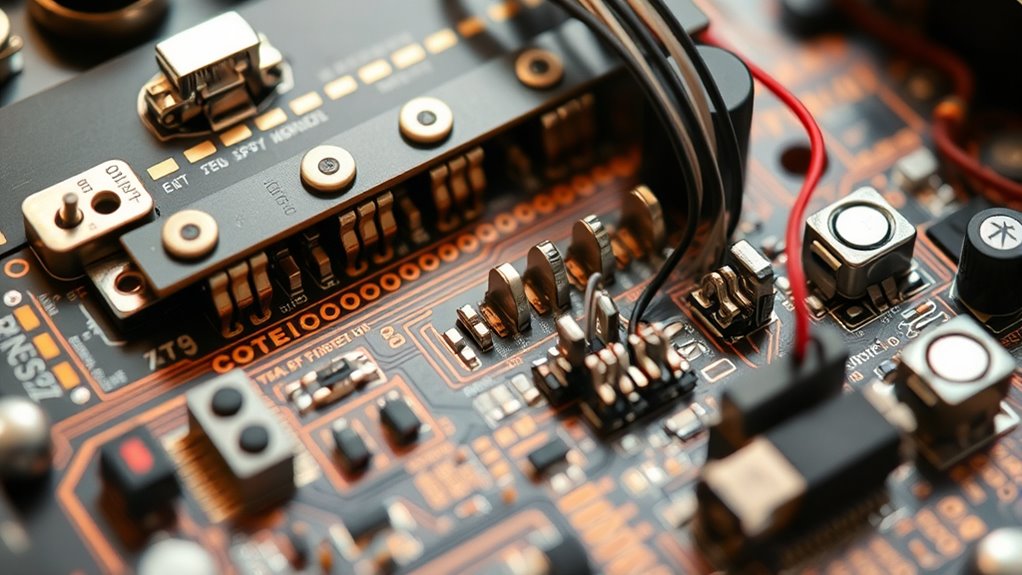

Electromechanical scoring systems rely on several key components that work together to evaluate and quantify performance accurately. Historically, these systems evolved from simple mechanical devices to sophisticated electronic setups, enhancing precision and reliability. The core components include motors, actuators, control units, and power supplies, all designed to perform specific functions efficiently. Maintenance procedures are essential for ensuring these parts operate smoothly; regular calibration, cleaning, and inspection prevent performance drift and mechanical failure. Understanding the historical development helps you appreciate how advancements have improved accuracy and durability. Proper maintenance minimizes downtime and extends the system’s lifespan, making it indispensable to follow manufacturer guidelines and schedule routine checks. These components form the foundation of a reliable electromechanical scoring system, ensuring consistent performance.

The Role of Sensors in Performance Detection

Sensors are essential for accurately detecting performance in electromechanical scoring systems. Understanding the different sensor types and their functions helps optimize data collection, while signal processing techniques guarantee reliable results. Proper calibration and attention to accuracy are key to maintaining trustworthy performance detection. Additionally, selecting sensors compatible with Kia Tuning modifications ensures precise readings during various enhancements.

Sensor Types and Functions

Have you ever wondered how performance detection systems accurately monitor the functioning of electromechanical devices? The key lies in different sensor types, each designed for specific functions. Temperature sensors track heat levels, while vibration sensors detect mechanical issues. Position sensors monitor movement and placement, vital for precise operation. To guarantee accuracy, proper sensor calibration is essential; it aligns the sensor’s readings with actual conditions. Sensor placement also matters—placing sensors in ideal locations ensures reliable data collection without interference. Some sensors, like current or voltage sensors, measure electrical parameters directly. Understanding the roles of various sensors and their correct calibration and placement allows you to maintain peak device performance and promptly identify issues before they escalate. Additionally, GMC tuning techniques can optimize sensor integration for enhanced vehicle diagnostics and performance monitoring.

Signal Processing Techniques

To accurately detect performance issues, signal processing techniques play a crucial role in interpreting data collected by sensors. You leverage noise filtering methods to eliminate unwanted signals, ensuring cleaner data for analysis. Neural networks come into play by recognizing complex patterns and anomalies that might indicate scoring errors or mechanical faults. These advanced algorithms learn from historical data, improving their ability to distinguish true performance signals from background noise. Proper filtering reduces false positives, while neural networks enhance detection accuracy. Together, they enable real-time assessment of electromechanical functions, helping you identify issues promptly. Additionally, crochet styles for locs can inspire innovative ways to customize sensor housings or protective covers, enhancing durability. By refining raw sensor signals through these techniques, you improve the reliability of performance detection, ultimately ensuring scoring precision and system integrity.

Accuracy and Calibration

Accurate performance detection depends heavily on the precision and proper calibration of the sensors used in your system. Sensor calibration ensures that measurements reflect true values, directly impacting measurement accuracy. Regular calibration aligns sensor outputs with known standards, reducing errors and maintaining consistency over time. Without proper calibration, sensor drift can occur, leading to inaccurate scoring results. You should routinely verify and adjust sensors to account for environmental changes or wear. High measurement accuracy depends on selecting sensors with suitable sensitivity and stability for your application. By maintaining proper calibration procedures, you ensure your electromechanical scoring system delivers reliable, precise data, ultimately improving overall scoring fairness and system performance. Proper sensor calibration is essential to uphold the integrity of your performance detection process. Additionally, implementing automated calibration protocols can help maintain sensor accuracy more efficiently over time.

Signal Processing and Data Conversion

Signal processing and data conversion are indispensable steps in electromechanical scoring systems because they transform raw sensor signals into meaningful information. You need to filter noise, amplify signals, and digitize data for analysis. This process guarantees accurate scoring results and efficient data handling. Key aspects include:

- Implementing wireless connectivity to transmit data seamlessly without physical connections.

- Using power management techniques to optimize battery life during continuous operation.

- Applying algorithms that convert analog signals into digital data for precise evaluation.

- Ensuring data integrity through error correction and calibration adjustments.

- Material selection plays a vital role in ensuring the durability and performance of the system components.

These steps are crucial for maintaining system reliability, especially in portable or remote scoring setups where stable power and wireless communication are critical. Proper signal processing guarantees accurate, real-time insights essential for fair and consistent scoring.

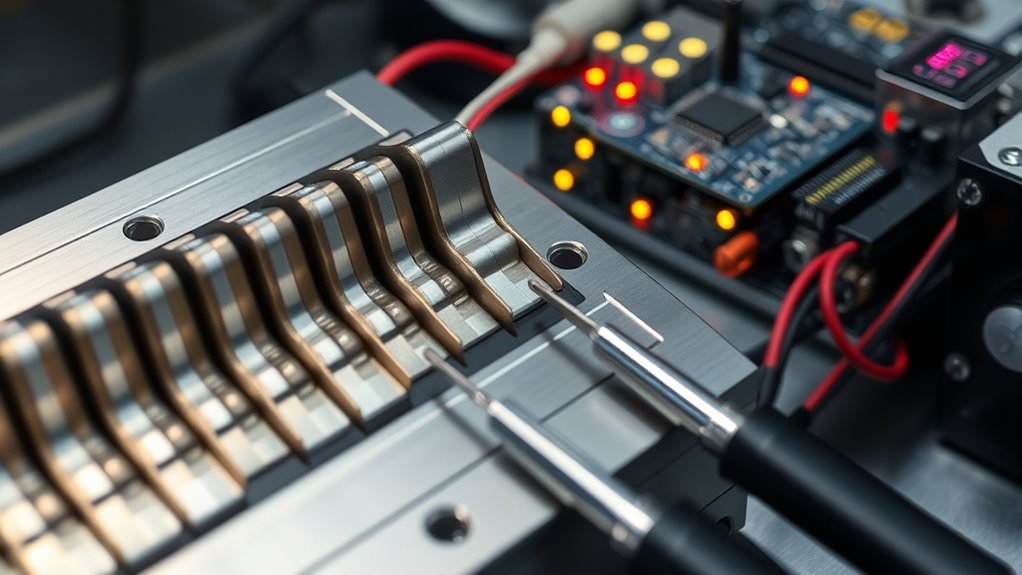

Mechanical Actuators and Their Functions

Mechanical actuators translate processed signals into physical movement, enabling electromechanical systems to perform their intended tasks. They convert electrical commands into motion using various power sources, such as hydraulic pressure and pneumatic systems. Hydraulic actuators use pressurized fluid to generate strong, precise movements, making them ideal for heavy-duty applications like scoring mechanisms that require force. Pneumatic systems, on the other hand, rely on compressed air to produce quick, lightweight motions, suitable for tasks needing rapid response. Your system uses these actuators to control the scoring blades or tools, ensuring accurate, reliable operation. By harnessing hydraulic pressure or pneumatic power, mechanical actuators translate electrical signals into controlled physical actions, forming the core of the electromechanical scoring process. Modern systems also incorporate efficiency ratings to optimize performance and reduce operational costs.

Integration of Electronic Control Units

You need to understand how the ECU’s role in scoring guarantees accuracy and consistency during competitions. Consider the communication protocols it uses to exchange data reliably with sensors and actuators. Recognizing these elements helps you grasp how seamless integration enhances the overall electromechanical system. Additionally, implementing security measures is crucial to protect the system against potential cyber threats and adversarial attacks.

ECU’s Role in Scoring

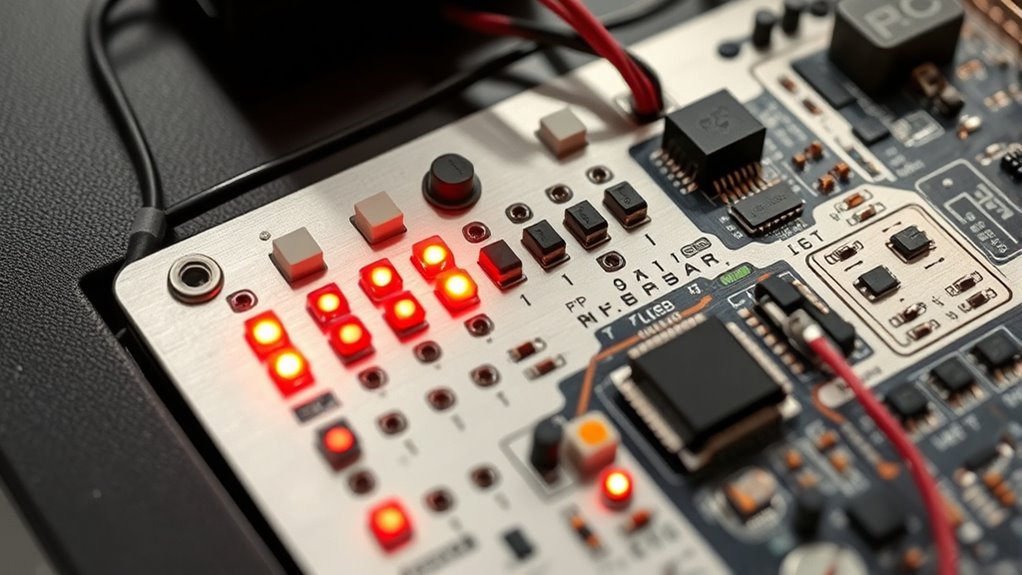

Electronic Control Units (ECUs) play a crucial role in scoring by seamlessly integrating data collection and decision-making processes during electromechanical competitions. You rely on ECUs to process inputs from sensors, including those used for video analysis, which helps evaluate performance accurately. Manual calibration ensures sensors remain precise, preventing errors in scoring. The ECU manages real-time data, determines if tasks are completed correctly, and transmits results to the scoring system. Additionally, understanding curiosity’s role in technological innovation can lead to more effective troubleshooting and system improvements.

Here are key functions:

- Collects sensor data for accurate assessment

- Incorporates video analysis for detailed evaluation

- Performs manual calibration to maintain sensor accuracy

- Automates scoring calculations to minimize human error

This integration ensures swift, accurate, and reliable scoring throughout the event.

Communication Protocols Utilized

How do ECUs communicate seamlessly during electromechanical competitions? They rely on robust communication protocols, often using wireless protocols like CAN bus or Wi-Fi for quick data transfer. These protocols enable real-time coordination between different ECUs, ensuring smooth scoring and system responses. To protect sensitive information, data encryption is essential—it prevents unauthorized access or tampering during transmission. Secure wireless protocols help maintain data integrity and confidentiality, even in noisy environments. Additionally, standardized communication methods reduce latency and improve reliability, which are critical in competitive settings. By combining efficient wireless protocols with strong data encryption, ECUs can exchange information securely and swiftly, ensuring the electromechanical scoring system operates accurately and without interruption.

Calibration and Accuracy Assurance

Ensuring precise measurements begins with thorough calibration and rigorous accuracy assurance processes. You start by performing calibration procedures to align sensors and mechanical components accurately. This step guarantees the scoring system reads inputs correctly and maintains consistency over time. Next, you implement accuracy validation, regularly testing the system against known standards to confirm its reliability. You should also document calibration results and schedule periodic recalibrations to prevent drift. Additionally, employing automated checks helps identify discrepancies early, maintaining high scoring fidelity. Incorporating advanced calibration techniques can further enhance measurement precision and reduce errors. By adhering to strict calibration procedures and continuously validating accuracy, you ensure the electromechanical scorer delivers dependable, precise results, reducing errors and increasing confidence in its performance.

Advantages Over Manual Scoring Methods

Automated electromechanical scoring offers significant advantages over manual methods by delivering faster, more consistent results. With wireless connectivity, your workflow becomes seamless, allowing real-time data transfer without physical connections. This reduces errors and saves time during data collection and analysis. The user interface is designed for simplicity, enabling you to operate the system easily, even without extensive technical training. Automated scoring minimizes human bias and variability, ensuring uniformity across samples. Additionally, it provides immediate feedback, helping you identify issues quickly. Overall, these features enhance efficiency, accuracy, and ease of use, making electromechanical scoring a superior choice over manual techniques. You’ll experience more reliable results and streamlined operations, elevating your experimental or assessment process. Moreover, vetted products ensure safety and effectiveness, giving you confidence in your scoring system implementation.

Frequently Asked Questions

How Do Electromechanical Scoring Systems Handle Multiple Simultaneous Inputs?

When you ask about multi input handling and simultaneous scoring, you’re curious how these systems process multiple signals at once. You’ll find that electromechanical scoring systems excel here, using advanced sensors and circuits to detect and record each input precisely. They handle simultaneous scoring by prioritizing signals or using parallel channels, ensuring every input is accurately captured without delay. This enables quick, reliable scoring even when multiple inputs happen at the same time.

What Safety Measures Are Integrated Into Electromechanical Scoring Devices?

You should know that electromechanical scoring devices incorporate safety protocols like protective barriers and warning signals to prevent accidents. They also feature emergency shutoffs that instantly halt operations if something goes wrong. Regular maintenance and safety checks ensure these measures stay effective. By following these safety measures, you help minimize risks, protect operators, and guarantee the device functions correctly during scoring.

Can Electromechanical Scoring Systems Be Customized for Different Sports or Activities?

Think of electromechanical scoring systems as chameleons, adaptable to every sport. You can customize them through sport-specific calibration, guaranteeing precision for each activity. Their modular design allows you to swap components easily, tailoring the system to different sports or activities. This flexibility means you won’t need multiple devices, saving time and money. With this approach, you guarantee accurate, fair scoring no matter the sport, like a well-tailored suit fitting perfectly every time.

How Is Data Stored and Retrieved From Electromechanical Scoring Systems?

You store and retrieve data from electromechanical scoring systems through data encoding, which converts scores into signals the system can process. The system uses memory storage to save scores and related information, guaranteeing quick access when needed. When you want to retrieve data, the system decodes the stored signals, allowing you to view the score. This process ensures accuracy and efficiency in managing scoring data during events.

What Maintenance Is Required to Ensure Long-Term Accuracy of These Systems?

Imagine your scoring system as a finely tuned instrument, needing regular care. You should perform calibration checks to guarantee its accuracy remains sharp, like a musician tuning their instrument. Lubrication schedules keep its moving parts smooth and responsive, preventing wear and tear. Regular maintenance, including these steps, guarantees your system stays precise over time, avoiding errors and prolonging its lifespan. Stay diligent, and your system will perform flawlessly for years.

Conclusion

Understanding how electromechanical scoring works is like opening a symphony of precision and technology. By combining sensors, actuators, and electronic control units, you create a system that scores with the accuracy of a master artist. This seamless integration transforms manual efforts into a harmonious dance of automation, ensuring fairness and consistency. Embrace this technology, and you’ll find yourself riding the wave of innovation, where every detail is finely tuned like a well-oiled machine.